chainless ebikes soon for sale!

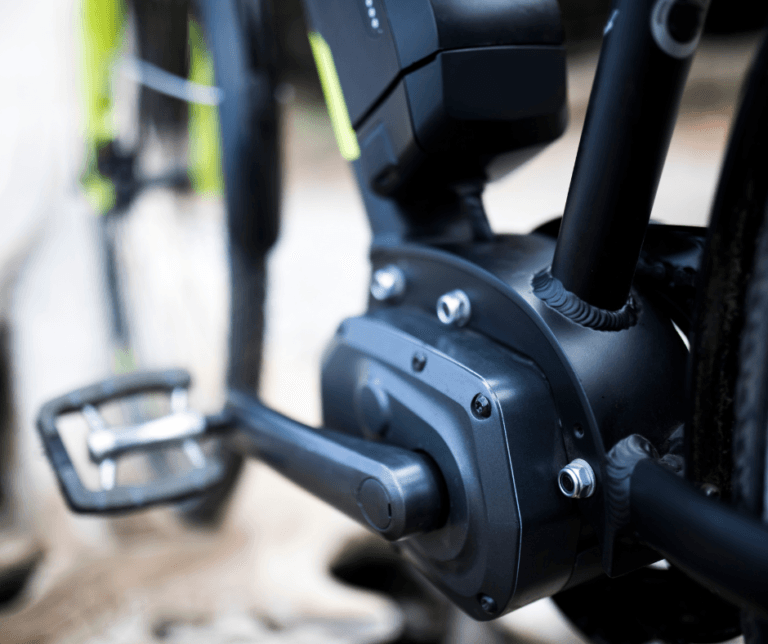

Four new Chainled Ebikes models designed by French manufacturer CixiThe Eurobikes 2025 will be sold. We analyze the pros and cons of one of the most interesting innovations of Ebikes discs. Pedals convert directly to an electric generator. The electricity produced is then transmitted to the rear hub engine.

Standard Battery Ebike Disc System and Digital discs without circuit

Let’s compare the effectiveness of the standard Ebiko pedal with the pedal energy recovery system or Pers, Pedal Energy Restore Systemas its manufacturer Cixi calls. We’ve already written here Schaefflerwhich creates another Ebike Drive system and circuit without a circuit I am sending football Folding in Ebike. It is quite a comparison of the efficiency of the normal pedal and the energy restoration of the pedal. In fact, the chain electric bike is completely lacking in the energy from the pedal, while its hub engine can also be supported by batteries, as in many cases, such as the Ebike below. Provided that the battery can be well maintained by supplying regeneration by supplying energy. This can accelerate its wear, for example, happens to the BMW i3 electric car. Its gasoline -driven range extension speeds up the battery to be worn by BMW.

Cixi attached to heritage chain without height in Ebike

Cixi with a heritage chain without a height specification

Chain Ebike Benefits compared to normal ebikes

- Lighter transmission system

- No gear wear, no greasy fingers

- Smooth and liquid automatic gear changes using an endless gear range

- Low operating costs, low maintenance

- Recharge while you are driving

- Wheel lock

- Braking before the lock

- Removes elbow dead areas, optimizes your pedal development technique

- More new EBIKE design options

- Organic

- Performance in various locations

Chain without Ebik’s flaws

- Lower driving efficiency, approximately 20% less

- Inadequate in a variety of driving situations where it is necessary to replace the changing gears

1. Lighter transmission system

A power generator, who is at the time of restriction, weighs something less than a kilo. The chain, cartridge, gear switch, conventional Ebiko circuit and battery can easily exceed 5 kg.

2. No gear wear

Because there are no portable mechanical parts.

3. Smooth and fluid automatic gear changes using the Infinite Gear range

Its software harmonizes an electric motor thrust with driving conditions, e.g.

4. Low -performance costs, low maintenance

The brakes last longer to stop the regenerative engine, no need to replace, clean and lubricate the chains, chains, etc.

5. Recharge while driving

By leading and renewing, thus extending the Ebike range.

6. Wheel lock

It blocks the rear wheel to prevent theft.

7. Braking before the lock

This enables gradually regenerative stopping.

8. Removes Crank dead locations, optimizes your pedal technique

As we are pedal, the pedal loop contains stains that are harder to use, for example, when both pedals are at the top/bottom. Using a digital disk, it avoids it. This can even match the necessary effort with the different strength of your feet if one of them was stronger than the other.

9. More new ebike design options

The absence of a chain, a chain ring and a cartridge expands the choice of Ebike design, such as folding Ebikes.

Chain Mando Footloos.

10. Environmentally friendly

Ecology, no less wearing battery. By optimizing battery consumption and increasing energy recovery, regenerative Ebika contributes to reduction of energy consumption and emissions associated with electricity production.

11. Performance in various areas

Regenerative systems can be particularly useful in hilly or urban areas with frequent Stop-And-go scenarios where the energy recovery is more significant.

Cixi Verdant, Chainleder E-Cargo Bike

Chain without Ebik’s flaws

1. Lower drive efficiency, approximately 20% less

In the usual Ebike energy stationed pedal, it would be good 95%to kinetic energy, resulting in rear wheel rotation and bike driving force. 5% losses result from the friction of mechanical components: chain, cartridge, pedals and chain. If the strength of the pedal is used for a generator supply, such as an Ebike without a circuit, there is another conversion between mechanical and electricity than using a battery. The latter’s engine turns the electric battery into mechanical energy, while first converts the mechanical energy of the pedal into electricity, which the engine turns back into mechanical energy. The process of turning Pedal energy into electric energy causes a generator 20% energy loss. That is, the energy of the pedal is transmitted to the circle by a 95% speed circuit, while this speed is reduced to 80% when the generator has turned into electricity to feed the engine. Then we have to shave 20% of that 80%, as the electric motor turns into motion or kinetic energy only 80% of its electricity, and the remaining 20% turn into heat and loss of friction. In total, only 64% of the muscle energy is transmitted to the circle used to the pedal generator.

Power generators convert mechanical energy into electric energy, but are currently inevitable loss of energy. The main areas where the loss of energy occurs includes:

1. Mechanical loss: These losses result from friction in moving parts such as bearings and resistance to air resistance (Wasta loss) in the generator.

2. Copper Losses: The resulting in generator edges, these losses result from the resistance of the wires, often referred to as (i^2r) loss, where (i) is a current flowing through the windings, and (R) is resistance.

3. Iron loss: Also known as core losses, which is due to variable magnetic field generator iron core. These include hysteresis loss and whirlpool loss.

-Histeri Loss: Causes magnetic field strength behind magnetizing forces in the main material.

-Deddy current loss: Causes circulating currents caused by conductive main material for alternating magnetic fields.

4. BLESS load loss: such losses are usually minor and result from leakage flows and unequal current distribution.

5. Brushes and contact loss: Losses in generators that use brushes are due to contact resistance between brushes and switches or slip rings.

2. Inadequate different riding situations where it is necessary to replace changing gears

When a lot of energy is needed, e.g. So they are inadequate for mountain bike sport.

See

Successful use of mechanical energy to produce electricity instead of movement

The Nissan electronic power technology is a unique hybrid force drive that uses an electric motor to drive wheels and the petrol engine is a generator to charge the battery. This setup allows the car to offer a driving electrical experience without the need for external charging. Nissan’s electronic power vehicles were usually strong, especially in markets such as Japan, where this technology has gained popularity. Models with electronic power such as Nissan Note and Nissan Serena have seen a favorable reception. Qashqai and X-Trail models in Europe have such technologies. Demand for e-gali is determined by consumer interest in better fuel efficiency and reduces emissions by maintaining the convenience of the traditional gasoline engine.

Nissan Qashqai

The conclusion: If the manufacturers succeed (have they succeeded?) Improve the electricity generator to the point, so that the very high percentage of the pedal energy is transformed into electricity, without the circuit, the EBIKS will enjoy a bright future.

Images: Cixi, Heritage Ebikes, Nissan

Advertisement: 667